IFFO's technical and regulatory work

Providing an update on IFFO technical and regulatory work, Dr Brett Glencross, IFFO's Technical Director, started with antioxidant regulations, noting that ethoxyquin is no longer an option for use in the EU, BHT reauthorisation is still under review, and for Tocopherols, the International Maritime Organisation codes for bulk shipping are progressing.

IFFO’s projects continue to progress, with ongoing work on novel antioxidants showing that the best alternatives are almost 80% equivalent to ethoxyquin. Fishmeal samples have been collected from both South America and North Atlantic for the microplastics origins and uptake project: microplastics predominantly enter at point-of-capture and fish trials show that there is nominal impact on fed species. Other ingredients were also measured and found to be more contaminated than fishmeal and fish oil. Finally, there are upcoming papers due to be published in the next months on metrics and a SWOT analysis (strengths, weaknesses, opportunities and threats) on novel proteins.

Will novel ingredients feed salmon tomorrow?

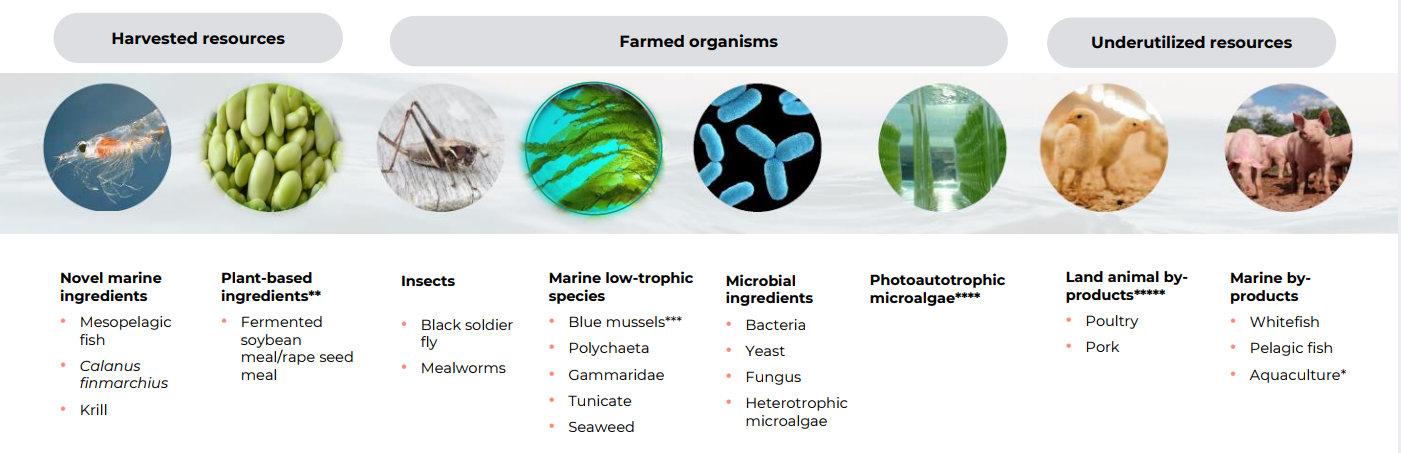

Exploring novel ingredients in salmon feed, Prof Margareth Øverland, from Norway’s Department of Animal and Aquaculture Sciences, explained that the salmon industry is facing a variety of constraints, including limited access to marine ingredients, dependence on important plant ingredients and increasing demand for sustainable raw materials. Sustainable feed is the key to future growth, she said: it is the largest emission and cost component, as well as sustainability drivers for consumers. There are several promising raw materials sources, shown below:

Exploring novel ingredients in salmon feed, Prof Margareth Øverland, from Norway’s Department of Animal and Aquaculture Sciences, explained that the salmon industry is facing a variety of constraints, including limited access to marine ingredients, dependence on important plant ingredients and increasing demand for sustainable raw materials. Sustainable feed is the key to future growth, she said: it is the largest emission and cost component, as well as sustainability drivers for consumers. There are several promising raw materials sources, shown below:

Øverland gave an overview of the strengths and barriers for upscaling these alternatives to a commercial level, as well as future actions.

More from less - turning CO2 into a sustainable, high-value feed ingredient

Presenting from an alternative feed perspective, Peter Rowe from Deep Branch (founded in 2018) discussed their Proton feed, a single-cell protein relying on carbon dioxide and hydrogen, developed for the animal feed industry. The ingredients are made from locally sourced ingredients to a bespoke nutritional profile. Still in the early stages of development, the pilot facility in the Netherlands will go live this year, with expected production at 2mt / year.

Presenting from an alternative feed perspective, Peter Rowe from Deep Branch (founded in 2018) discussed their Proton feed, a single-cell protein relying on carbon dioxide and hydrogen, developed for the animal feed industry. The ingredients are made from locally sourced ingredients to a bespoke nutritional profile. Still in the early stages of development, the pilot facility in the Netherlands will go live this year, with expected production at 2mt / year.

Insect protein as a sustainable feed ingredient for aquaculture

Moving to insect feed, Nizar El Alami presented on behalf of Innovafeed, a biotech company and insect producer for animal nutrition, founded in 2017, that developed an innovative circular and zero-waste industrial process by co-locating its production sites with agro-industrial partners. This valorizes locally available starch co-products and waste energy reducing CO2 emissions per year with an industrial-scale production of high-quality feed ingredients. Through the breeding of the Black Soldier Fly (Hermetia illucens) into a feed ingredients for animal feed, the vertical farm system ensures a reduced footprint in terms of land use and does not compete with agricultural land. Global output expected by 2030 is at 100,000mt / year. "We have a protein challenge. Several solutions are available. We aim to be complementary with other ingredients and are actively looking to explore collaboration opportunities throughout the sector".

Moving to insect feed, Nizar El Alami presented on behalf of Innovafeed, a biotech company and insect producer for animal nutrition, founded in 2017, that developed an innovative circular and zero-waste industrial process by co-locating its production sites with agro-industrial partners. This valorizes locally available starch co-products and waste energy reducing CO2 emissions per year with an industrial-scale production of high-quality feed ingredients. Through the breeding of the Black Soldier Fly (Hermetia illucens) into a feed ingredients for animal feed, the vertical farm system ensures a reduced footprint in terms of land use and does not compete with agricultural land. Global output expected by 2030 is at 100,000mt / year. "We have a protein challenge. Several solutions are available. We aim to be complementary with other ingredients and are actively looking to explore collaboration opportunities throughout the sector".

Corn Fermented Protein from the Dry Grind Bioethanol Process

Focusing on corn fermented protein (CFP), Prof Peter E.V. Williams from Green Plains Inc noted that this new plant-based protein (up to 60% crude protein) is produced using the mechanical separation of the whole stillage from the dry grind bioethanol process. Current production is in excess of 600ktons per annum from multiple sites which produce a very consistent product. The product has functional characteristics based on its spent yeast components. Plant based co-products, secondary products generated during a manufacturing process have a unique position in that they do not demand additional acreage and do not compete with human food consumption therefore contributing to a circular economy.

Focusing on corn fermented protein (CFP), Prof Peter E.V. Williams from Green Plains Inc noted that this new plant-based protein (up to 60% crude protein) is produced using the mechanical separation of the whole stillage from the dry grind bioethanol process. Current production is in excess of 600ktons per annum from multiple sites which produce a very consistent product. The product has functional characteristics based on its spent yeast components. Plant based co-products, secondary products generated during a manufacturing process have a unique position in that they do not demand additional acreage and do not compete with human food consumption therefore contributing to a circular economy.

Raw materials use in aquafeed and creation of novel opportunities

From BioMar, Fernando Norambuena, discussed the evolution of aquafeed diet composition, highlighting the impacts on greenhouse gas emissions and looking into 2030. Aquaculture feed is responsible for up to 80% of the environmental impact of producing seafood. "In BioMar, we encourage and stimulate restorative practices in our supply chain and have set targets for minimum inclusion levels of circular and restorative ingredients. We define restorative ingredients as raw materials that significantly shift the balance between ecosystem impacts and human production systems." By-products and trimmings have a key role to play there. Norambuena finished by underlining that BioMar has set verifiable science-based targets through the Science Based Targets initiative (SBTi) and has committed to ambitious GHG emissions reduction targets following the 1.5°C pathway.

From BioMar, Fernando Norambuena, discussed the evolution of aquafeed diet composition, highlighting the impacts on greenhouse gas emissions and looking into 2030. Aquaculture feed is responsible for up to 80% of the environmental impact of producing seafood. "In BioMar, we encourage and stimulate restorative practices in our supply chain and have set targets for minimum inclusion levels of circular and restorative ingredients. We define restorative ingredients as raw materials that significantly shift the balance between ecosystem impacts and human production systems." By-products and trimmings have a key role to play there. Norambuena finished by underlining that BioMar has set verifiable science-based targets through the Science Based Targets initiative (SBTi) and has committed to ambitious GHG emissions reduction targets following the 1.5°C pathway.

Panel Discussion: Where to next in the novels story

The panel discussion that followed first focused on the added value that novel protein sources can provide. This is where partnerships play an important role, allowing producers to understand how consumers feel about the new products and what their expectations are.

Developing a better understanding among consumers

As Biomar's Fernando Norembuena put it: "We need to help our customers understand where we want to go, as cost and scale are not competitive enough for now. We want these new materials to work as a protein source. We need to focus on their protein and energy values and then, after that we consider other functional values."

As Biomar's Fernando Norembuena put it: "We need to help our customers understand where we want to go, as cost and scale are not competitive enough for now. We want these new materials to work as a protein source. We need to focus on their protein and energy values and then, after that we consider other functional values."

Prof Margareth Øverland, from Norway’s Department of Animal and Aquaculture Sciences, insisted that these novel feed ingredients do have value beyond their nutritional value: "We need to take our experiments a step further and challenge the fish with pathogens, and see what happens. With insects, it is about the bioactive components. It is believed that they can help improve the robustness of the fish".

New products mean new value chains as well as a shift in people's mindset. "We shouldn't just rely on the planet. Carbon, hydrogen, nitrogen, are the most simple blocks that we also need to consider", Peter Rowe, from Deep Branch added, while Nizar El Alami, from Innovafeed, mentioned the potential of genetics in insects, as another strategy yet to be explored.

Maturity of technologies will be key to reaching expectations in terms of production volumes: "If we want to be competitive and have a strong demand, we need time: time is needed to build plants", Nizar El Alami insisted.

Making the most of diversity

"For our corn fermented protein we are looking at a range of different enzymes to use in the 50 hour fermentation process" stated Green Plains' Peter Williams. Collaboration is needed to progress and complementarity is the way forward, all the panellists agreed: "There is no silver bullet. Several ingredients, as well as trimmings, are needed and can complement each other nicely. We may also want to make a more regional use of fishmeals, combined with novel ingredients", Nizar El Alami concluded.