Quality standards are upheld using best practice and traceability all the way from high seas catch via modern fishmeal and fish oil processing techniques through to the end user.

Catching

The feed grade fish caught for fishmeal production are mainly small oily short-lived, fast-growing fish with little demand for human consumption. They are caught using fishing nets with government specified mesh sizes. The area where they are caught and the time of catching will be determined by government controls to ensure quotas are upheld. Many vessels carry trackers which allow satellite tracking. This assists government authorities to check fishing is done within the agreed areas and times. Additionally, boats are often checked on landing. Their catch is monitored for type of fish caught, size, where they are caught and time of catching. Usually refrigerated seawater is used to chill the fish and keep them fresh, avoiding damage.

Processing

As fish is discharged at the factory it is weighed and sampled. Most IFFO Members sample at this point to check fish freshness which is monitored using TVN; fishermen may be paid based on the weight of catch and its TVN (freshness) to encourage high quality raw material to be landed.

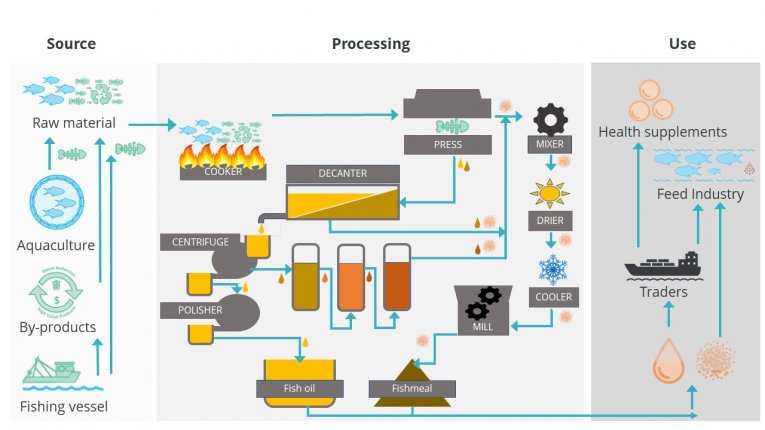

Fish is first typically cooked to coagulate protein and allow some oil to be released, using a temperature of 85°C to 90°C. In addition micro-organisms are killed by this process (see diagram). Clean conveyors, holds and storage pits, short storage time and reduced temperatures minimise micro-organisms and the spoilage they may cause. The lower temperatures also reduce fish enzyme activity (autolysis), another form of spoilage. Cooked fish then passes into a screw press where liquor is pressed out and the solids (press-cake) go to the drier.

The liquor is decanted to remove further solids. It is then centrifuged to spin off oil and separate out an aqueous phase (stickwater). The stickwater passes through evaporators to reduce its volume (concentrate). This concentrated liquor (called stickwater because it tends to be viscous and sticky) is returned to the press cake entering the drier. A typical drier contains coils through which super-heated steam passes. These coils raise the temperature to 90°C (controlled by flow rate etc) for drying to around 10% moisture after cooling. Low temperature driers such as indirect hot-air or vacuum driers, operate at lower temperatures.

Fish oil may go on to be purified to remove solid impurities; special filters can be used where appropriate to remove some fat soluble impurities. More sophisticated refining is used to produce a clear odourless liquid for pharmaceutical/nutraceutical uses e.g. capsules.

Handling

Fishmeal contains no carbohydrate. At a dry matter content of 90% it will not support microbial growth. But it can pick up micro-organisms from extraneous material. Hygiene through the process is extremely important. This is controlled using the schemes detailed below. During fishmeal handling cleanliness is paramount to ensure no cross-contamination. Fishmeal can be stored in 25kg bags, one tonne bulk bags, or in bulk in warehouses, to await transport.

Fishmeal plants must only handle fish - they cannot handle material from any other animal. Extremely tight controls are now in place in many countries including EU and Japan to monitor fishmeal to ensure it is free of land animal material, in common with controls on other raw materials.

Most factories operated by IFFO Members have in place HACCP schemes (Hazard Analysis Critical Control Points) to ensure safe production and assured quality. This involves outside inspectors who ensure critical control points are correctly identified and controls carefully monitored and recorded e.g. product temperature, moisture, microbial count etc. Any deviation outside tolerance limits is investigated and quickly resolved with full documentation for future reference.

Producers supplying markets within the European Union are being encouraged to adopt the International Feed Standard Alliance (IFSA) quality assurance scheme. This covers quality assurance from raw material through the factory, storage and transport to the end user. It includes the Dutch GMP+ and UK Femas schemes and is expected to become the main quality assurance scheme for raw materials across Europe and elsewhere.

Follow link to obtain the FAO Fisheries Technical Paper T142: "The production of fishmeal and oil"

Product Composition

As fishmeal is produced from fish with some water and oil removed, its composition reflects that of the fish raw material. IFFO producers are committed to undertake this production with minimal change in nutritional value. Raw material is handled rapidly and mainly chilled to prevent spoilage.

Standard fishmeal: they are referred to as "fair average quality" (FAQ) when the drying phase is direct hot air, and are ideal for poultry, ruminants and omnivorous fish. For carnivorous fish, crustacea and baby pigs, special products are more suitable. Although they cost more because of the need for even fresher raw material and special drying, they have been shown to be cost effective for these more sensitive species.

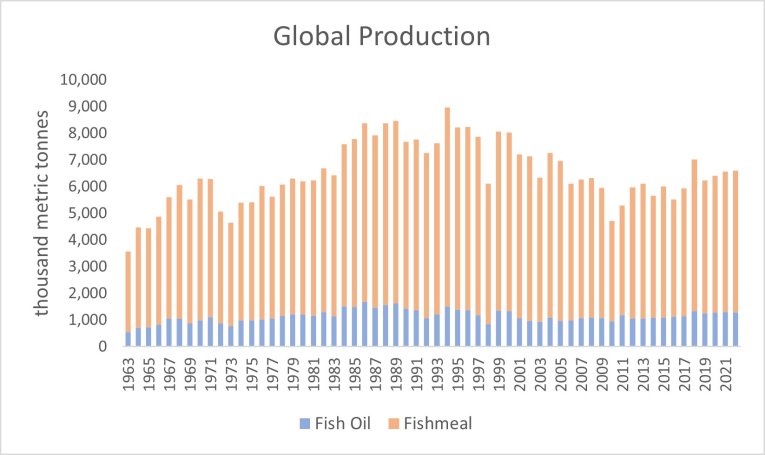

Source: IFFO (2023)

Standard fishmeal typically has 64% to 67% crude protein with up to 12% fat. Special products tend to have more protein - 68% to 72%. They also have a lower amine content reflecting fresher raw material e.g. maximum 1000 ppm histamine. For standard/FAQ products amine limits are generally not needed and therefore not normally specified.

For special fishmeal products processing is gentle. Special driers are needed-typically indirect hot air or vacuum drying. A special product with low temperature drying is referred to as an LT or Super Prime meal. If the special driers are not available, a special product can be produced which is slightly less digestible - two or three units less as determined in fish.

To check for gentle drying, pepsin solubility gives an approximate guide. For special products it should be over 92%. Digestibility determined in the target animal is a more reliable method, but expensive. This should be 89% or higher for LT/super prime products. For standard meals pepsin solubility will generally be over 85%.

Note: The above figures are guidelines only and are not intended for contractual purposes.